Grain dryer RMX

Continuous grain dryer RMX with a capacity from 20 to 250 t/h, is an advanced development of the engineering department of the ROMAX plant. The design of RMX grain dryer combines the benefits of the most efficient technologies and studies over many centuries in its segment.

RMX grain dryer — SIMPLE! RELIABLE! EFFECTIVE!

- High quality drying of cereals, legumes and oilseed crops.

- The drying chamber, through which the product moves, has no analogues in the world!

- The process of drying is carried out in continuous flow of grain movement.

- There are no dead zones or grain clogging.

- The product is constantly in the air flow.

- The product volume in the dryer is 2 times less in comparison with the mixed flow grain dryer.

- Delicate drying mode allows to dry brewing barley and seeds.

- The new design of the grain dryer allows to use its energy efficiently.

- A new unit for mixing of hot air flows has been developed, which increases the efficiency factor of the dryer.

- The drying chamber has no common elements with the outer casing of the unit, which maintains a homogeneous microclimate and prevents from heat loss.

- Grain and warm air flows do not come in contact with the environment.

- Simple control system for operator`s convenience is provided.

|

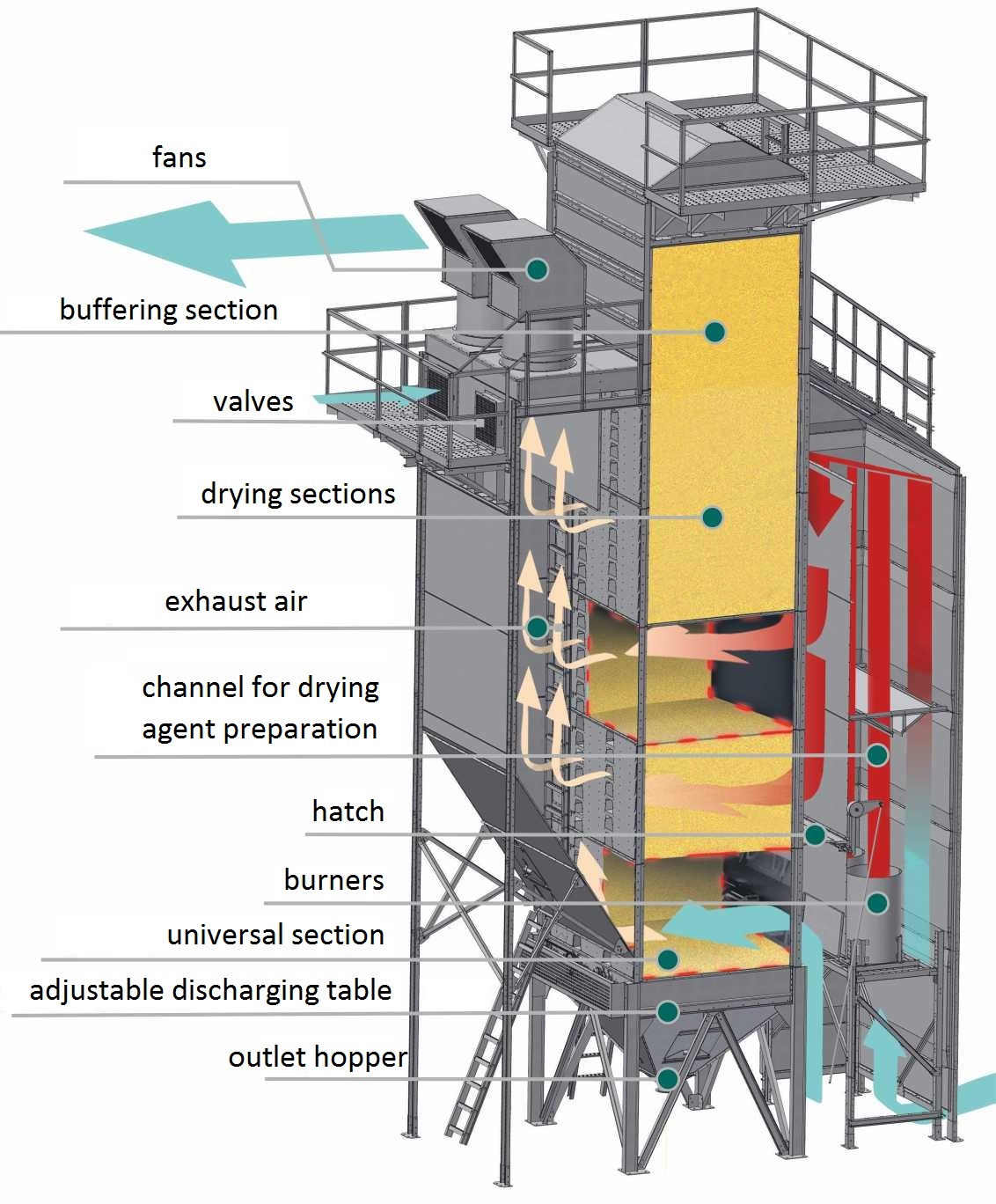

The grain is loaded into the grain dryer, filling the buffering, drying and cooling (universal section). |