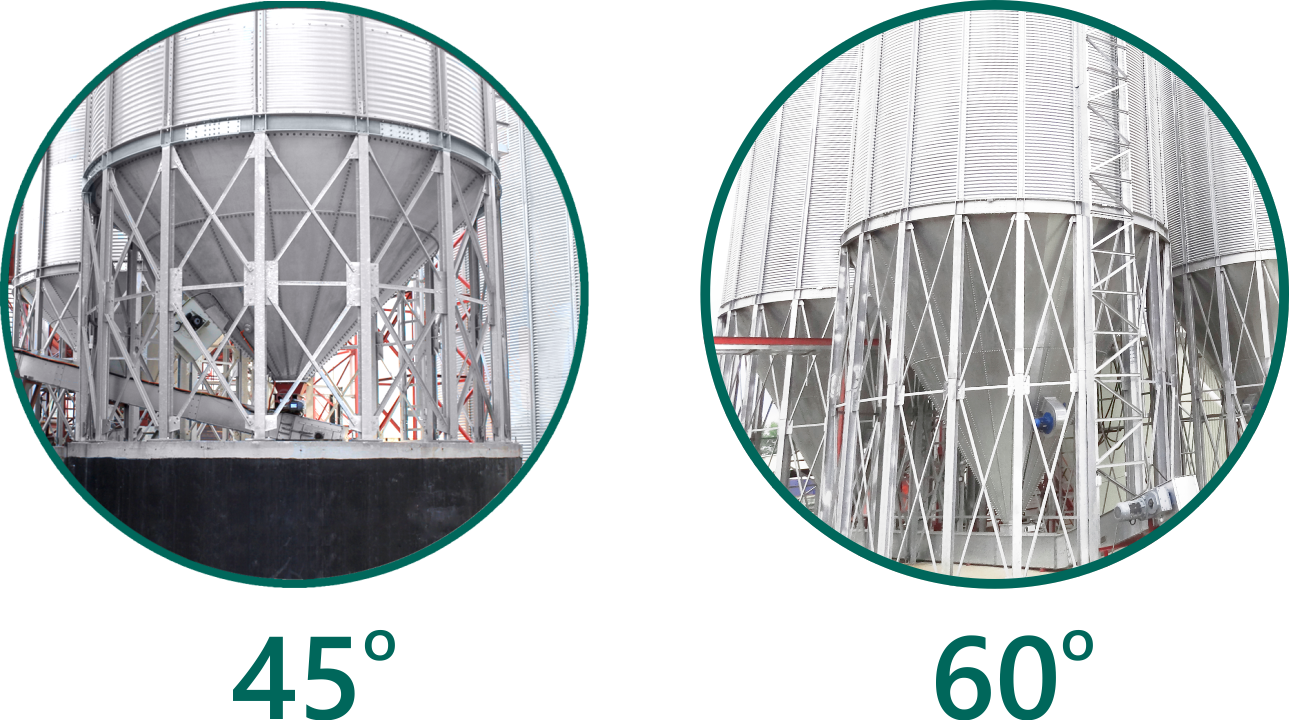

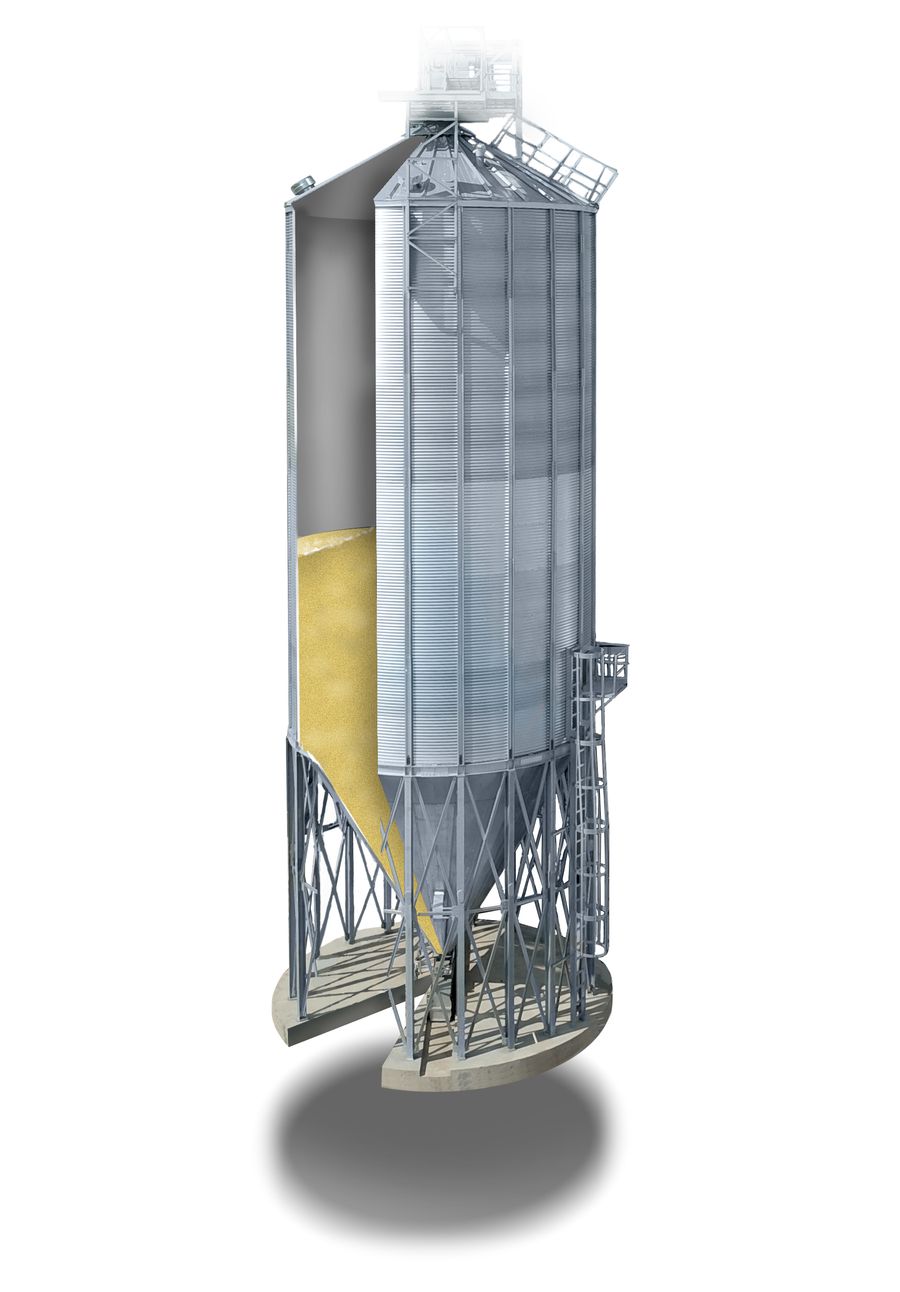

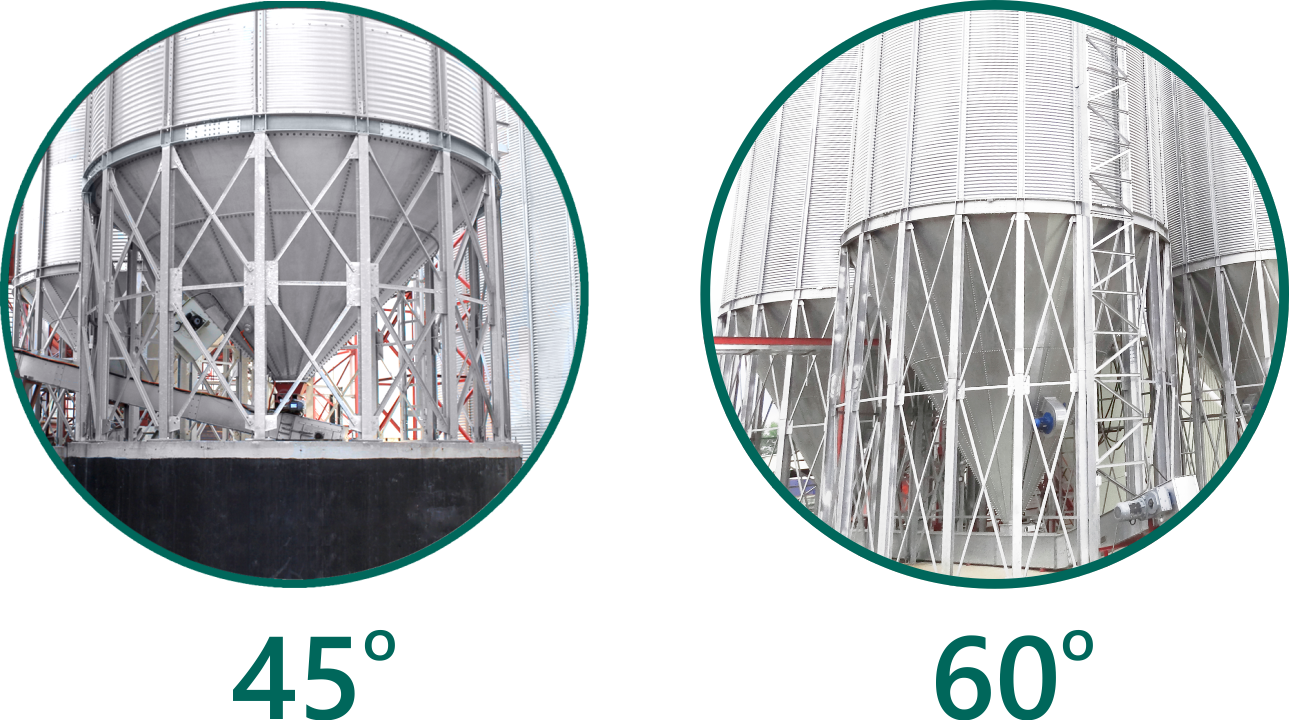

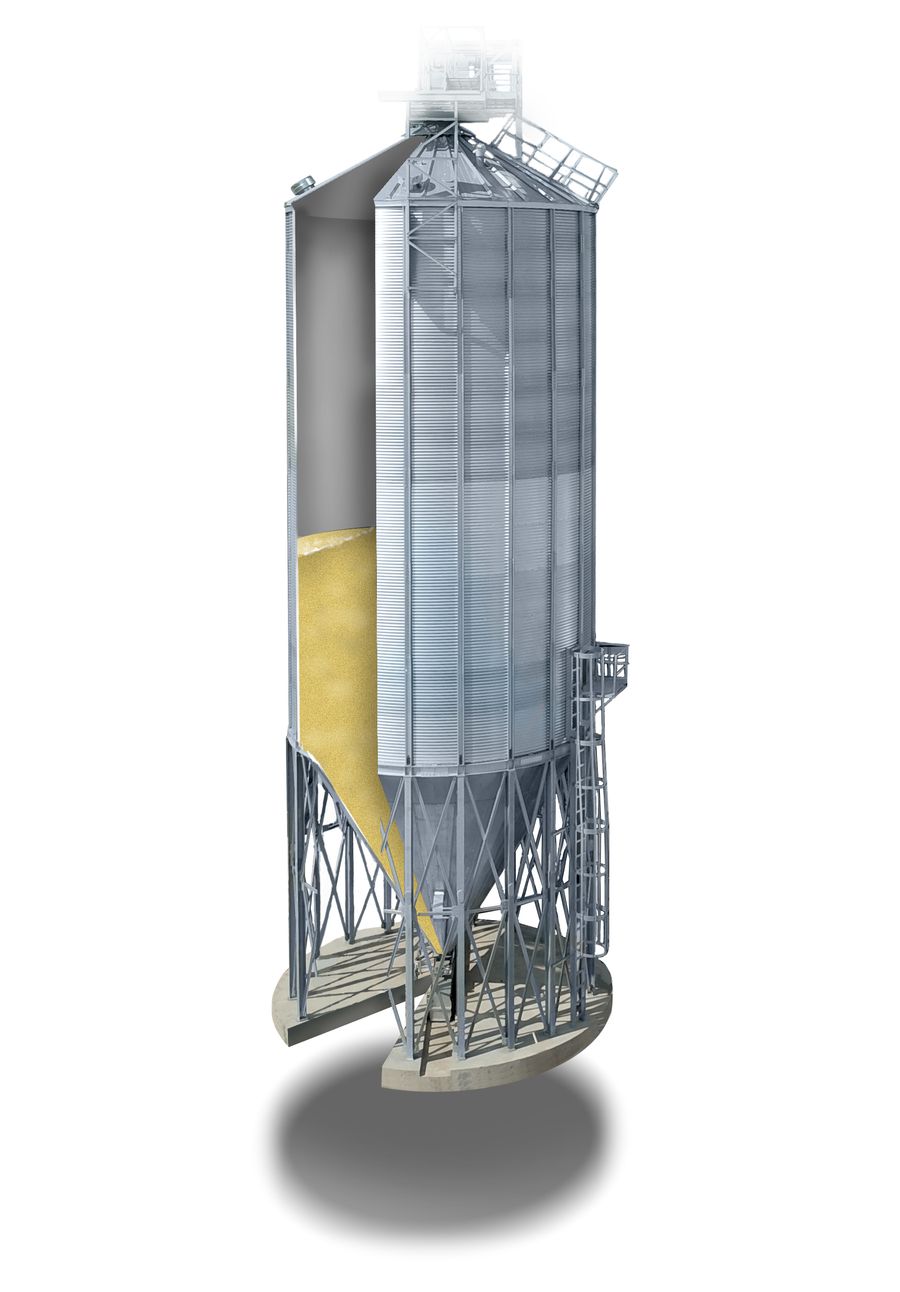

Cone-type big-size silos are used for temporary grain storage with its further discharge by gravity flow without additional discharge systems. Bottom of cone-type silos has an angle of inclination — 45°, for raw and hard-running materials — 60° and 66°.

Storage volume of the cone-type silos:

— 45° silo bottom — from 153 m³ to 2643 m³;

— 60° silo bottom — from 162 m³ to 1253 m³.

Hatches, ladders and rest platforms make it possible to perform maintenance, cleaning and repair of component parts of the silo tank.

Compression rings with supports are supplied covered with hot dip galvanizing or powder coating, as agreed with the customer.

Grain silo manufactured by the ROMAX plant can be operated in all atmospheric conditions without any additional covers.

1

Silo roof

2

Roof inspection door

3

Ladder from the roof inspection door to the top of the roof

4

Silo walls

5

Service hatch on the silo wall

6

Service platform for access to the service hatch on the silo wall

7

Ladder outside the silo from the floor to the service hatch

8

Compression ring

9

Delicate grain loading system (optional)

10

Conveying equipment for grain discharge

11

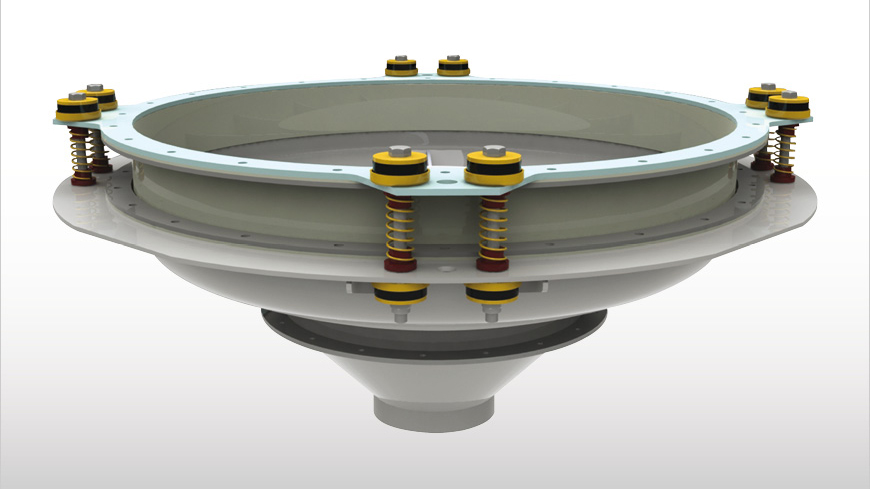

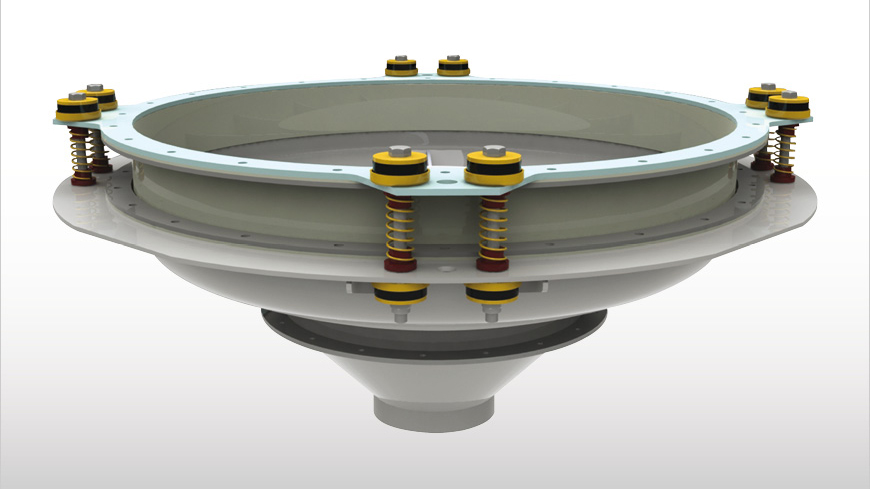

Vibrating bottom (optional)

12

Fans

13

Cone bottom aeration

14

Roof air ducts

15

Roof turbo-deflector

AVAILABLE SLOPE ANGLES OF THE CONE: