Grain-cleaning machines ALFA

A model range of grain cleaning machines ALFA is the own development of the ROMAX plant. It is in high demand among the owners of the farms and grain processing enterprises.

Grain cleaning machines ALFA 100 (as well as 50, 150, 200 t/h) are separators for preliminary cleaning of legumes, cereals and grain crops from impurities. This grain

ALFA - SIMPLE! RELIABLE! EFFICIENT!

Preliminary cleaning

50 - 200 t/h

Description of grain cleaning machine ALFA (50, 100, 150, 200 t/h)

This is a

The operation of the unit is based on the aerodynamic principle of separation of grain from impurities. The main machine working members are: gear motor and electric motor, cleaning module and

Design of grain cleaner ALFA was advanced in 2022. Now the following options are included in basic configuration of the machine:

- Removable block of the screen conveyor.

- Beater with an adjustable slide gate.

- Level sensor.

- Rotary valve.

Advantages of grain cleaning machines ALFA:

- Easy maintenance of the machine - a removable screen conveyor unit allows to carry out the service maintenance in a matter of minutes.

- Efficiency in case of any humidity level of grain– a rotary valve for light impurities prevents the product from sticking and it also ensures thorough discharge of impurities.

- The presence of a beater that distributes the grain product across the entire width of the screen conveyor.

- An additional product divider is integrated, which separates the flow of grain movement. It ensures a uniform product supply to the aspiration suction channel.

- Modified cross-flow fan with increased efficiency ensures uniform air injection across the entire width of the aspiration channel. It provides high quality cleaning of grain from light impurities.

- The drive of the main working members of the machine is carried out by a reliable gear motor and electric motor, which ensure the reliability and long-term operation of the cleaner.

- The body of the grain cleaning machine is made of high quality galvanized steel, which provides maximum corrosion resistance and therefore a longer service life.

- Multi-functional performance of wheat cleaner - the possibility of fine adjustment of the air flow for products with different impurity and humidity levels.

In addition to this, the body and all driving units of grain cleaning machine are made of high quality galvanized steel, which prevents product from sticking, provides an

Before the introduction of this grain

But the main advantage is easy maintenance of the machine. It is very important after a hard working day to clean

Operation process

|

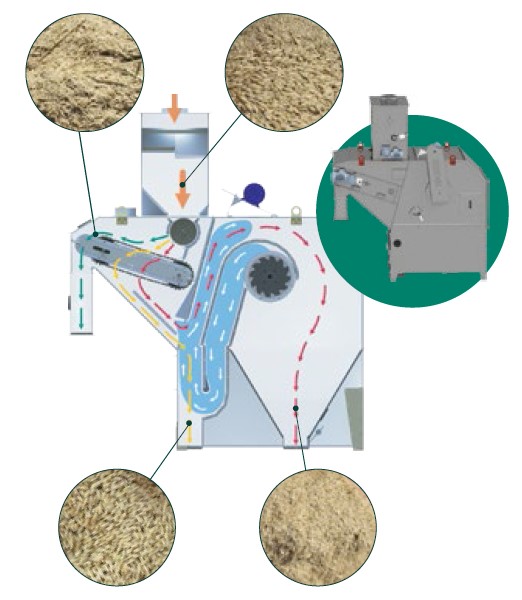

Product to be cleaned Coarse impurities Processed material Light impurities Air flow of the aspiration section |

The component parts of the machine operate the following way:

The main working members of the machine are: cleaning module 5 and air cleaning section 3. The working members are driven by gear motor and electric motor. The grain heap enters the storage bin, complete with a beater and an adjustable slide gate of the product 1, where it is accumulated and uniformly distributed across the width of the screen conveyor 7 by means of the beater 4 in the entire model range of machinery. The cleaning module consists of the screen conveyor, a driving shaft 2 and driven shafts 6. The tension of the screen is carried out by moving of the driving shaft by means of tension bolts and is determined by the chain slack.

Grain, light and fine impurities pass through it and coarse impurities (straw, ears, etc.) are discharged from the machine by the screen conveyor 7.

The material, passed through the screen conveyor 7, is divided into two flows and enters the aspiration suction channel 8. Then the product passes through the blockage sensor 13, which is designed to turn off the machine when the outlet bin is clogged with grain. The closed air flow is produced by a

| Model | ALFA 50 |

ALFA 100 |

ALFA 150 |

ALFA 200 |

| Capacity, t/h | 50 | 100 | 150 | 200 |

| Weight with a full set of working members, kg | 980 | 1180 | 1250 | 1300 |

| Power, kW | 6,22 | 6,22 | 7,72 | 9,72 |

|

Overall dimensions with a storage bin (L/W/H), mm |

2900*1795*3150 | 2900*1795*3350 | 3045*1795*3350 | 3045*1985*3350 |

| Height with a storage bin, mm | 3150 | 3350 | 3350 | 3350 |

| Air output, m3/h | 800-1200 | |||

About company

ROMAX plant is one of the leading companies in Russia which manufactures agricultural equipment. You can buy a grain cleaning machine ALFA at the manufacturer’s price. The equipment presented in our catalogue is certified and meets international quality and safety standards.

The way we work

For the production of grain cleaning equipment, we use our own developments, implemented on the basis of the modern technologies. Product samples are collected on the

We provide a

Why is it profitable to contact ROMAX?

With a purchase of grain cleaning machine ALFA 100 as well as 50, 150, 200 t/h, manufactured by the ROMAX plant, you will receive:

- personal approach;

long-term guarantee;- faultless provision of services;

- manufacturer`s prices;

- an interesting loyalty system for both regular and new customers.

If you have any questions, please contact our manager by phone or in another way convenient for you.

Our services

|

|

|

|

|