Bucket elevator

|

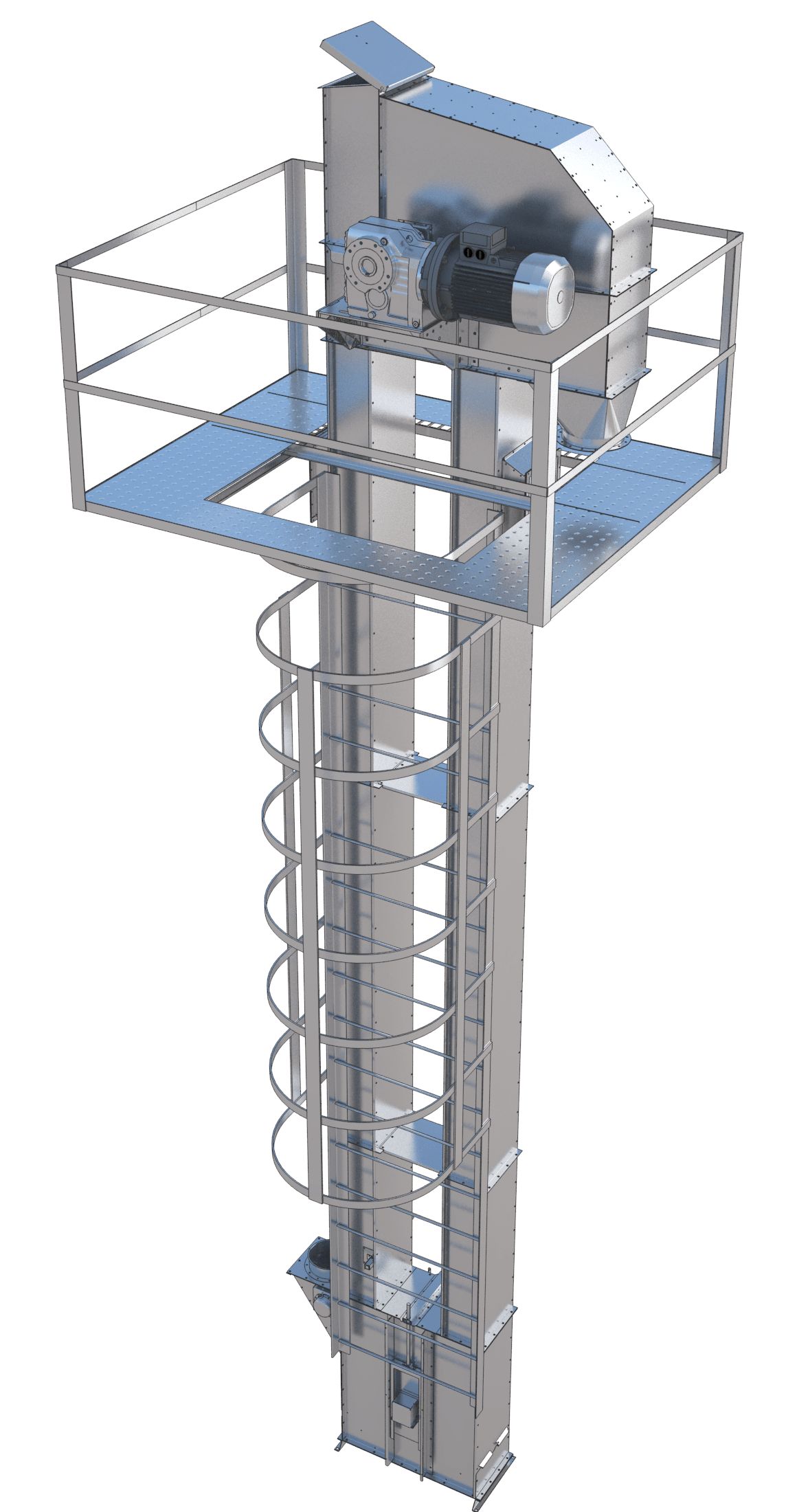

The capacity of bucket elevators for grain is from 5 to 600 t/h. The standard model range of equipment comes complete with The main idea is to provide the user with reliable equipment and to guarantee its |

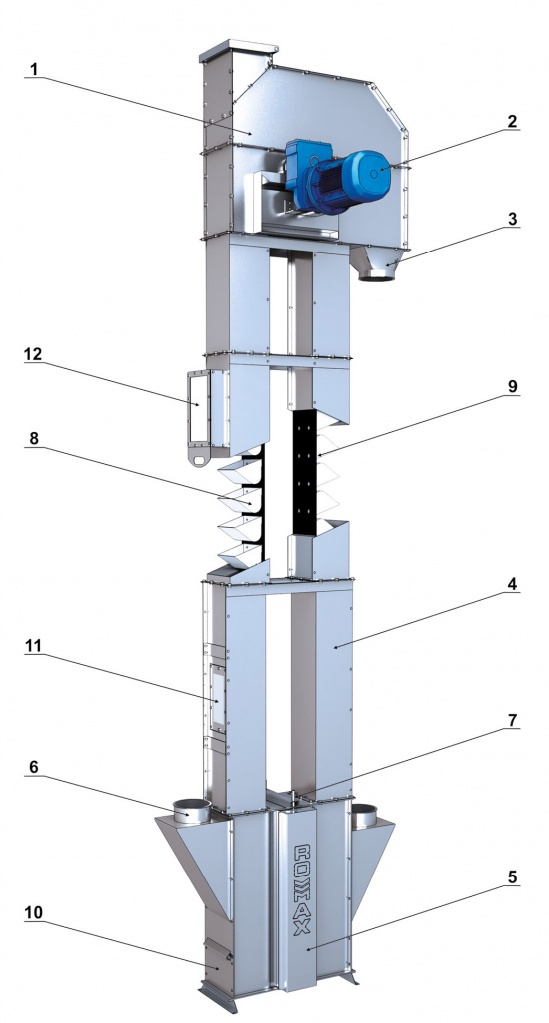

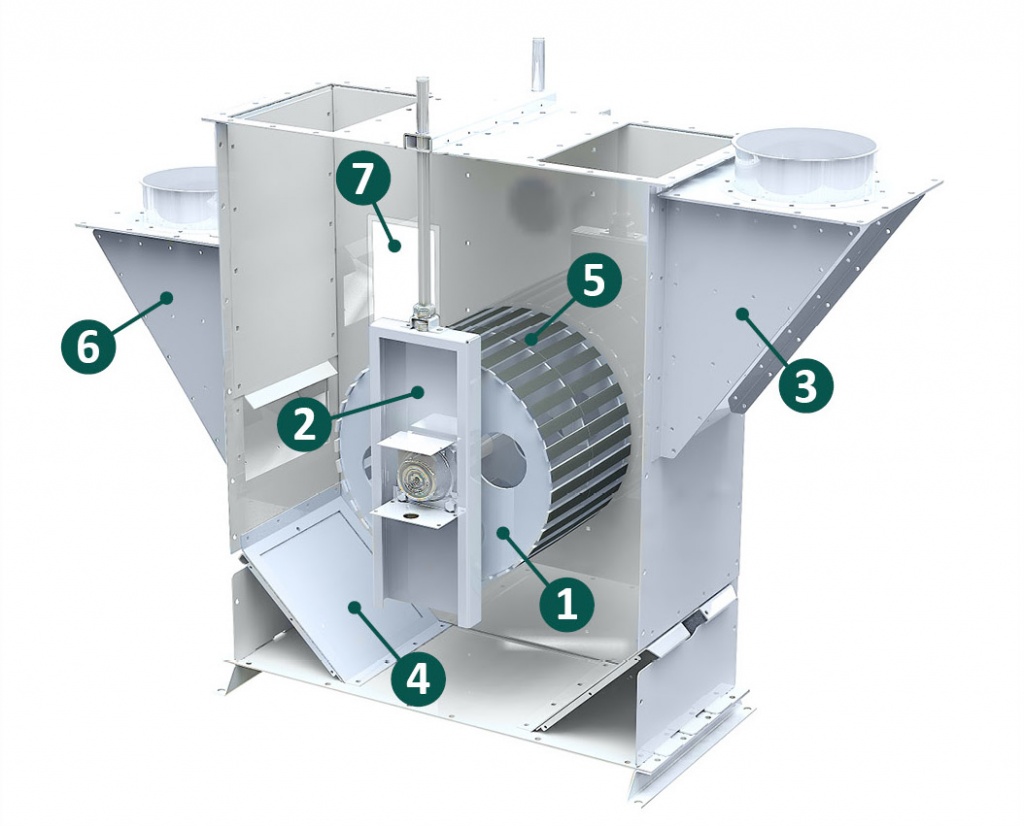

Bucket elevator component parts: |

|

|

1. Elevator head |

7. Tensioning mechanism |

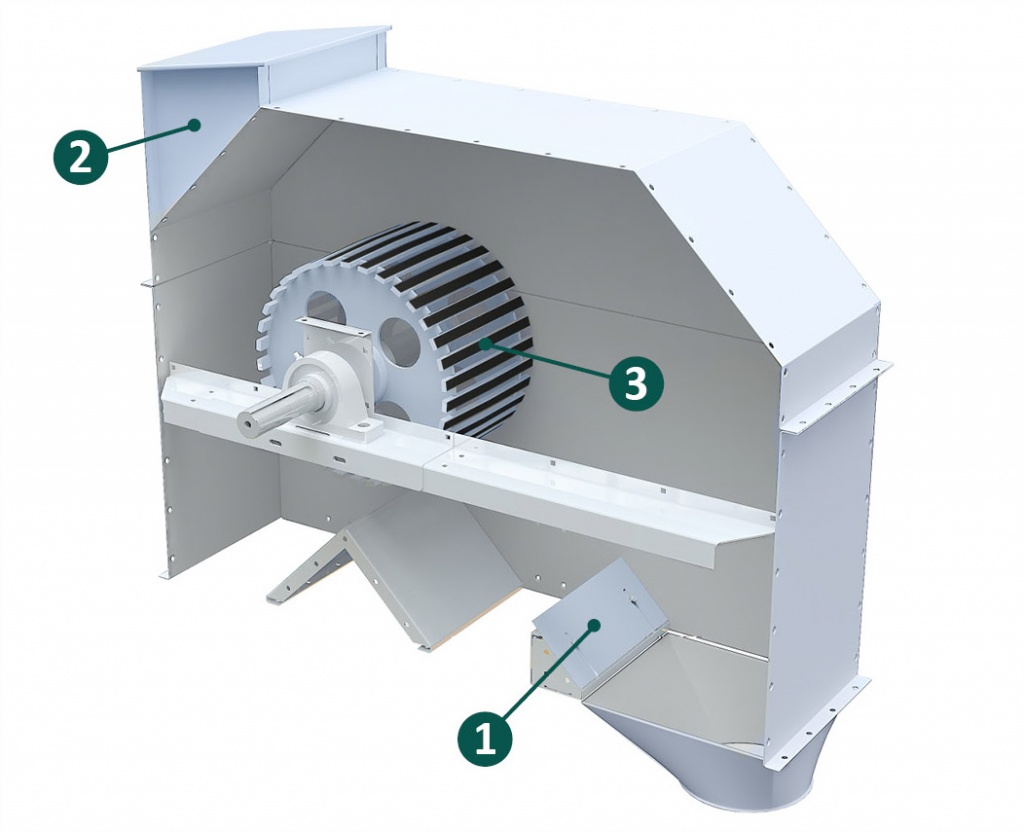

Elevator head

- It is made of galvanized steel. The top cover of the bucket elevator head is lined with a 10 mm thick polymer plate, which increases the service life of the unit and reduces a product damage.

- An adjustable plate (1) between the bucket and outlet section makes it possible to prevent the product from spilling back to the shaft.

- The explosion relief panel (2) is mounted on the top of elevator head.

- Optionally, for units with high capacity (above 350 tons per hour), the drum with rubber protective covering (3) is provided.

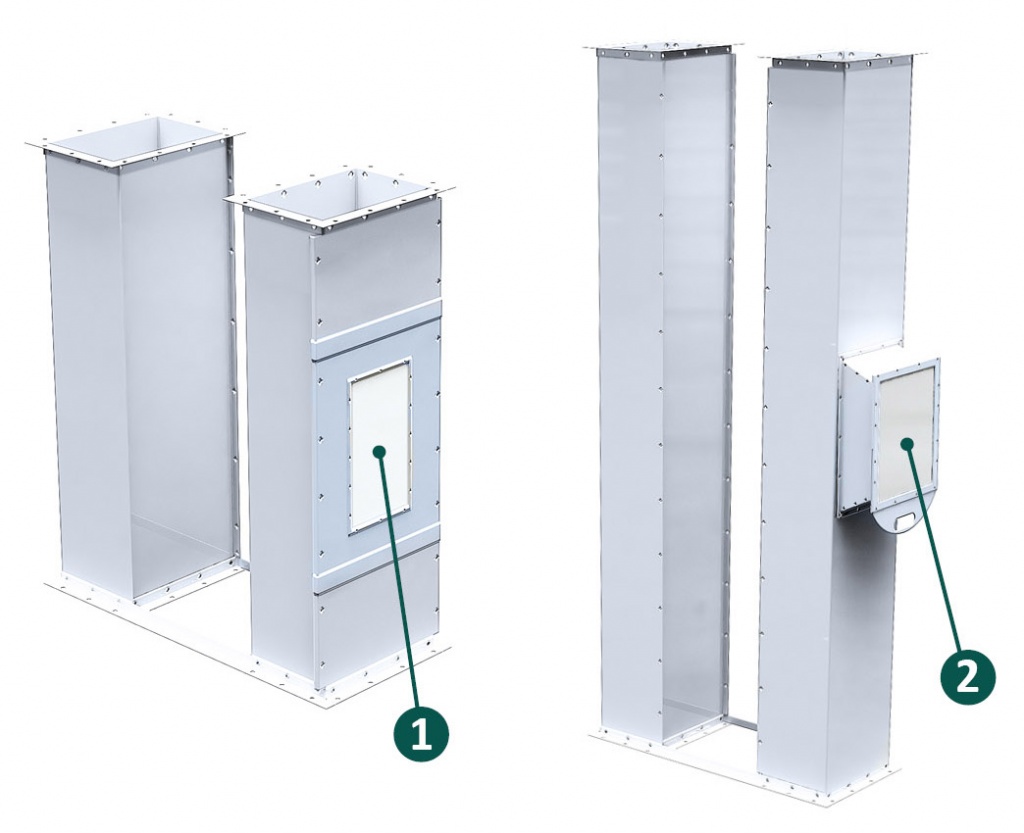

Shaft

- It is made of galvanized steel. It is supplied disassembled to provide more space during the shipment of equipment to the installation site.

- The units can be assembled fast and without special tools due to the high quality manufacturing of the parts. It ensures absence of error in the design process of connecting holes and mounting seats.

- Explosion relief panels (2) and special inspection windows (1) are installed in the shafts during installation. That is included in the complete set of the unit.

Elevator boot

- It is made of galvanized steel. It comes complete with a hollow drum (1) with a belt tensioning mechanism (2) and inlet bin (3), lined with a 10 mm thick polymer plate. There are slide gates (4) on both sides of the boot lower part for convenient cleaning of the unit.

- It can be optionally supplied with a drum with rubber protective covering (5) for bucket elevators with high capacity, additional inlet bin (6) and inspection windows (7).

Technical specification

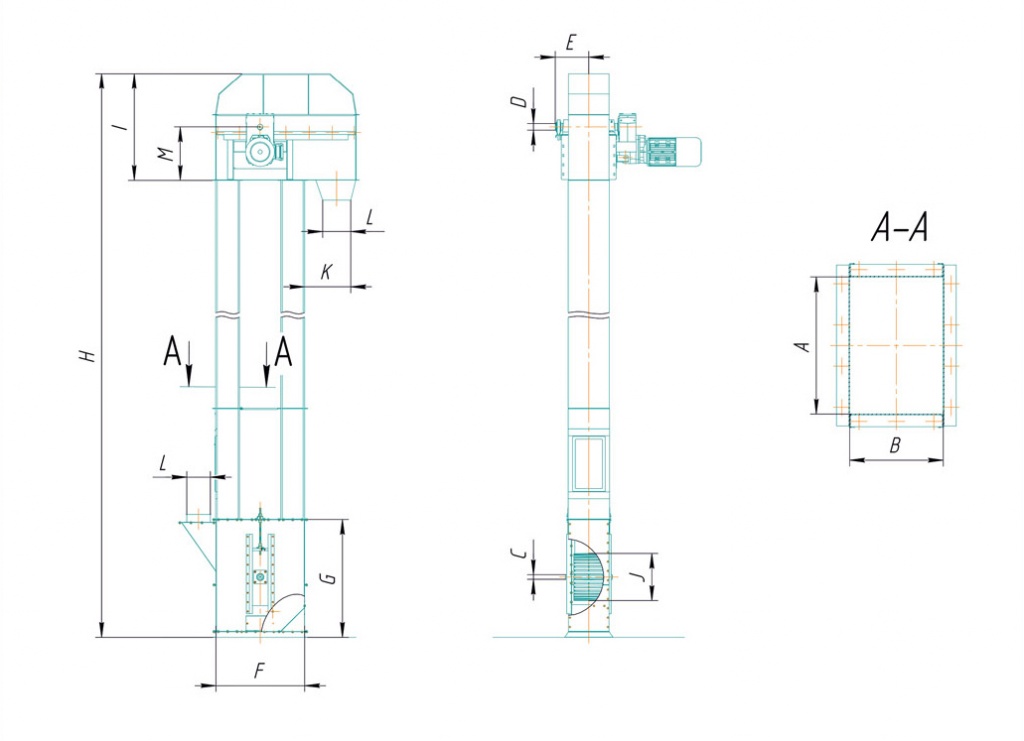

| TYPE | A | B | C | D | E | F | G | H | I | J | K | L | M | Capacity, t/h |

| E80 | 130 | 600 | ∅30 | ∅40 | 135 | 428 | 500 | - | 440 | ∅160 | 220 | 130 | 220 | 5–15 |

| E130 | 190 | 190 | ∅30 | ∅40 | 175 | 643 | 750 | - | 750 | ∅315 | 300 | 160 | 300 | 20–40 |

| E180 | 260 | 220 | ∅30 | ∅50 | 280 | 770 | 1008 | - | 900 | ∅385 | 380 | 200 | 385 | 40–80 |

| E280 | 365 | 250 | ∅50 | ∅70 | 350 | 954 | 1206 | - | 1200 | ∅500 | 550 | 250 | 580 | 80–150 |

| E320 | 365 | 300 | ∅50 | ∅70 | 350 | 1054 | 1206 | - | 1200 | ∅500 | 500 | 300 | 580 | 150–200 |

| E370 | 500 | 340 | ∅60 | ∅100 | 420 | 1250 | 1420 | - | 1540 | ∅630 | 650 | 300 | 700 | 160–350 |

| E450 | 600 | 325 | ∅60 | ∅100 | 500 | 1250 | 1450 | - | 1400 | ∅630 | 670 | 400 | 700 | 350–450 |

| E740 | 950 | 350 | ∅70 | ∅110 | 680 | 1470 | 1750 | - | 1650 | ∅800 | 690 | 500 | 850 |

About company

Our company has rich experience in cooperation with European partners. These mutually beneficial business relations have become a fundamental basis for improving manufacturing activities and producing

For the manufacture of specialized grain processing systems, we use advanced

The service department of our company has only certified employees specializing in various fields of activity: electrician, mechanics, automation. The presence of the service department is necessary since the operational period of any equipment depends not only on the manufacturing quality, but also on the engineering design features, installation work, and maintenance. The specialists of the ROMAX plant carry out installation and commissioning of grain processing complexes. There is no need to worry about the smooth functioning of grain processing and storage equipment of the complexes.

Bucket elevator

Bucket elevator is a special unit for transportation of bulk grain products. The buckets are fixed on the vertical conveyor, which, when conveying, lift the grain up and dump it into the intake hopper of another unit or onto the conveyor belt.

Such bucket elevators differ from chain conveyors in higher structural strength, durability and capacity. Another difference that speaks in their favor is light weight, relatively small dimensions and low cost. Therefore, most farms prefer this variant, which is the most optimal.

The

Our plant offers customers bucket elevators with a support structure (installed separately) and without it (supposed to be installed in elevator towers). Each model is completed with high quality materials and component parts. The prices for bucket elevators, manufactured by ROMAX plant, have an obvious advantage over the cost of the similar products, manufactured by competitive companies.

The way we work

The ROMAX plant, equipped with unique

At the beginning of 2019, the ROMAX company has sold an impressive amount of grain processing equipment and grain storage complexes. If you refer this to real grain volumes, you get more than 3 000 000 tons.

We cooperate not only with large companies, but also with small farms. So we manage to study in detail the needs of different segments of the agricultural industry in order to focus on them in our work, expanding the range of services provided. Improving the functionality of our agricultural machinery, we increase sales in Russia and in foreign markets.

Grain processing is a profitable but very difficult process, which we know perfectly well. It is possible to minimize losses and achieve high standards only with the help of

Benefits of cooperation with the ROMAX company:

- Working with us, you will enlist support of a reliable and honest partner.

- You can count on

on-time service. - Provision of a training program of special equipment operation.

- You receive guarantees in the form of licenses and certificates for our products.

When planning the purchase of a grain bucket elevator and other specialized equipment for grain processing, please contact us on the website zavodromax.com online or by phone.